Production System Optimization and Strategic Process Improvement

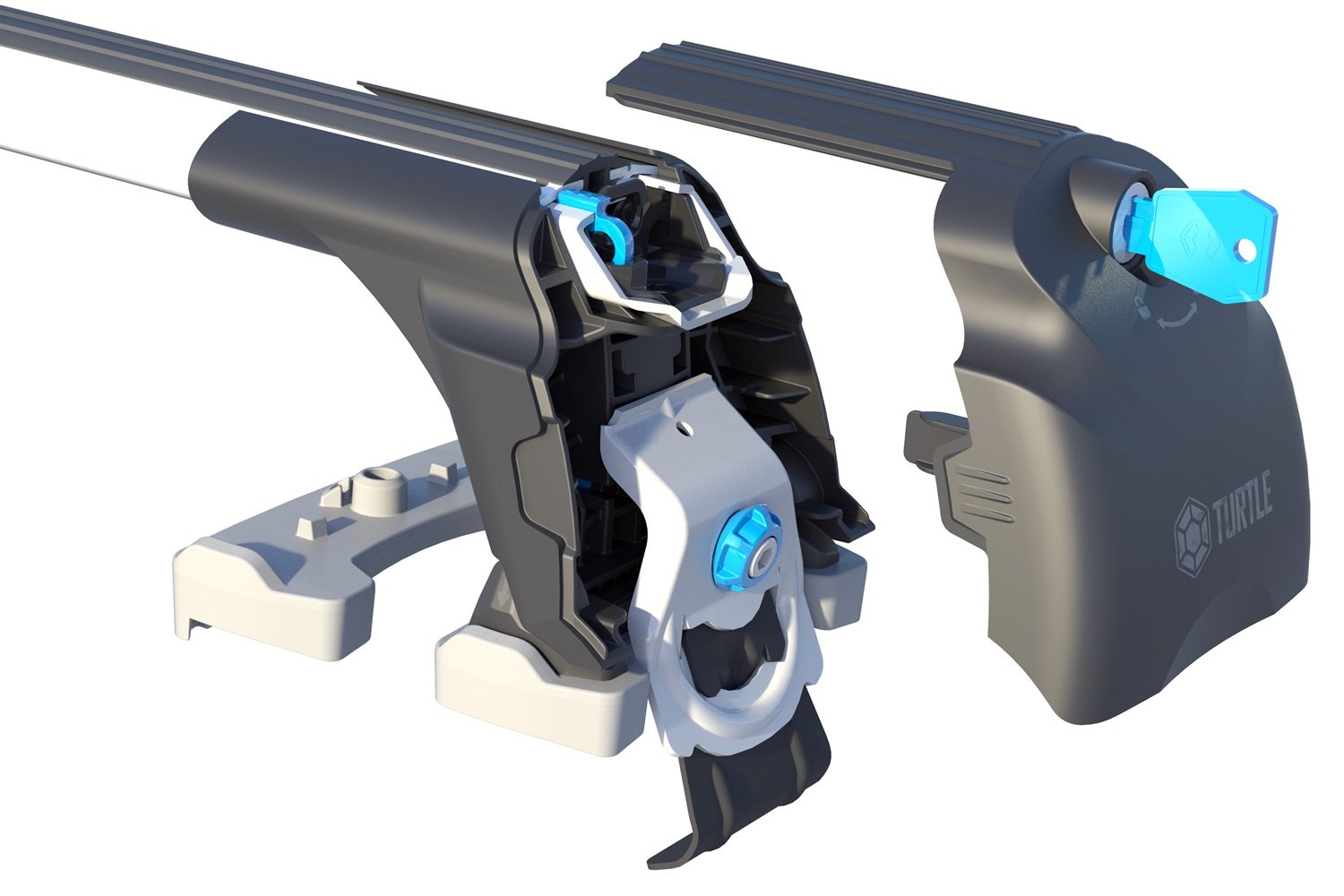

Transform your production processes with lean manufacturing methodologies to maximize efficiency. I provide comprehensive optimization for your production lines using proven methods like Just-In-Time, 5S, Kanban, One-Piece Flow, Poka-Yoke, and Kaizen. Through these efforts, your company can gain clear visibility into its true costs and profitability, allowing you to pinpoint areas for improvement.

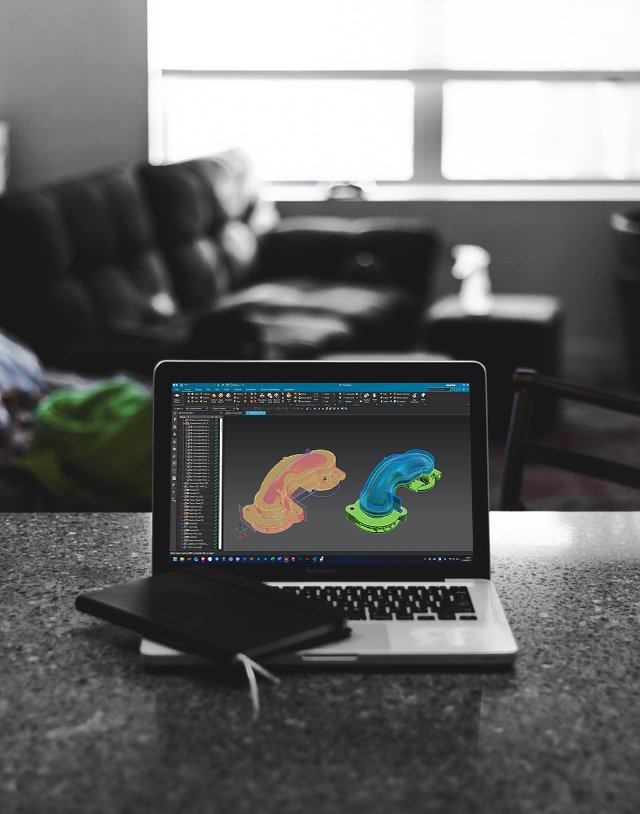

I completely restructure all your processes, including route/operation and workstation layouts, to the creation of conversational code systems and variant/non-variant material card definitions. I implement a Material Requirements Planning (MRP) system based on product bills of materials, production orders, and safety stocks, creating a flawless and sustainable workflow that uses resources in the most efficient way. I also provide the necessary training for your team to easily adapt to the new system, supporting your journey of stable yet agile growth.